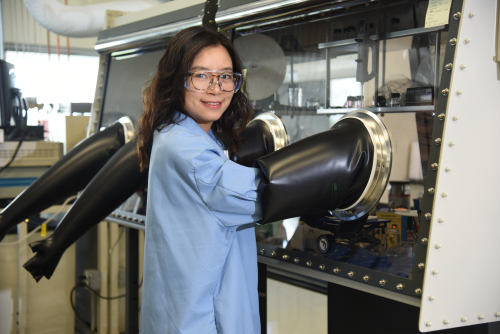

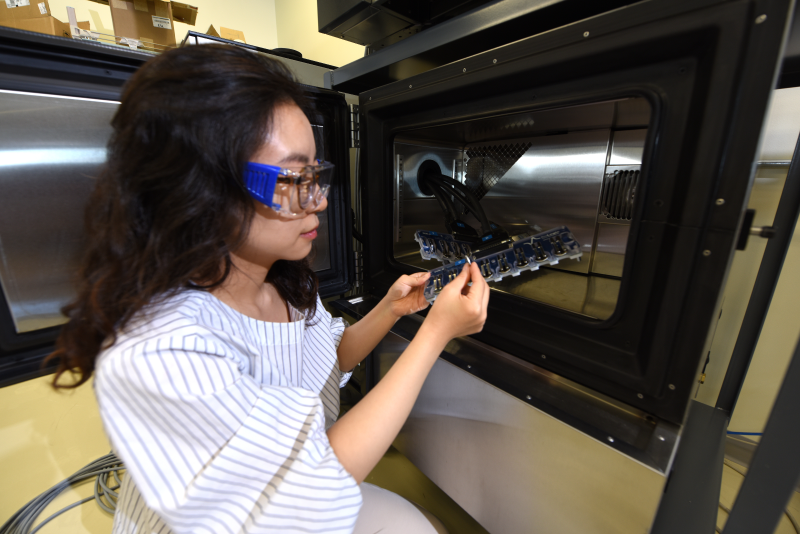

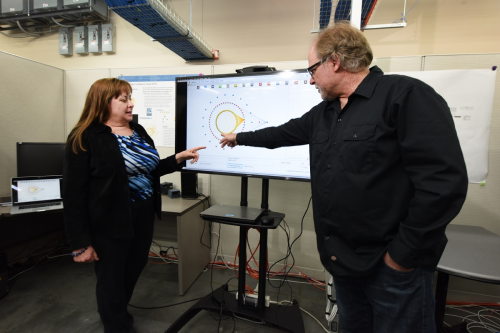

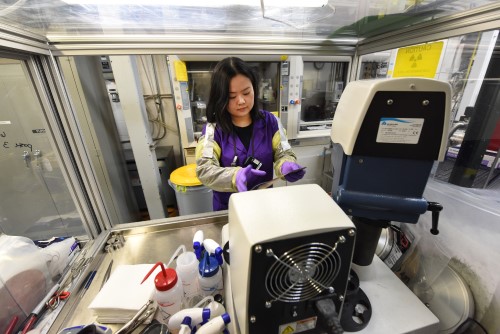

| | 1. Headline |  | Growing up in Northern China, Dr. Ningshengjie Gao and her family would prepare for scheduled area power outages meant to conserve energy. Her mother would cook meals to last the family for the duration, and they'd plan for Gao to visit her grandparents in a nearby, but different region, so she could do her homework with more light than the candles they'd use during the blackout. Those few summer days were not a big ordeal for Gao and her family, but the periods of time without electricity were enough to teach Gao at a young age about energy's importance in her daily life and the world. Today, Gao is a postdoctoral researcher in the Energy Storage and Advanced Transportation department at Idaho National Laboratory studying energy storage and conversion. Her two current projects work with carbon dioxide reduction and lithium metal batteries. Gao's parents had science backgrounds. Her father teaches at a medical school, and her mother is a mechanical engineering professor. But Gao's scientific path was far from ordained. She entered Nankai University in China for her undergraduate studies uncertain what career path she might follow – until she entered a chemical lab. It was not the discovery or experiment possibilities that made an impression. It was all the crystal-clear glassware shining in the room. Gao found them pretty. "I've always loved sparkly things," she said.  Gao put an assembled coin cell into a cell holder, which will then be tested later in an environmental chamber to test how the cell reacts in different temperatures, humidity levels, and pressures. It might have been the glassware that got her in the lab, but it was the science that kept her returning. Her efforts rewarded her with an international award during the 2013 World Engineering Summit held in Singapore. Gao loved conducting experiments. She still does. "It provides a continuous experience of exploring the world," she said. In the lab, "I am excited to witness new phenomena or processes that have never been seen before. I am doing things I cannot do in my daily life." In her daily life she does yoga, she hikes, and she investigates objects, like flowers, by quietly sketching them. In the lab, she is working to better understand energy, how to convert it, how to store it, how to use it safely and minimize its impact, and how to get more of it directly into everyone's hands in the form of electronic devices with batteries that last longer. Gao graduated with a bachelor's degree in 2013, and a few months later she entered a doctorate program at Oregon State University, where she focused on electrochemistry for energy applications. Specifically, she worked on technology to recover electrical energy and fuels from organic wastes. In the back of her mind, she remembered those days as a child without electricity at home in China. "In general, energy is critical across the world," she said. Gao finished her doctorate program last year, but her research at Idaho National Laboratory still investigates energy storage and conversion. One of her projects involves electrochemical carbon dioxide reduction. It is a project she started on two years ago as an intern at INL and involves using renewable energy to reduce the carbon footprint. She's currently working on how to convert renewable energy into a more dispatchable form to easily integrate into the electrical grid for long-term storage and transport. She recently helped draft a paper about this work that has been submitted for review for publication. Her other area of research focuses on lithium metal batteries. Lithium metal batteries have a higher theoretical capacity than lithium ion batteries, she said. But there are still issues with making it largely applicable to daily life. In the lab, Gao assembles batteries and then tests them. She runs them until they die in various conditions and collects the data. She is looking at battery failure mechanisms – why the battery cell dies. She looks at battery failure mechanisms to predict the lifespan of lithium metal batteries. Understanding how to make batteries last longer could have implications for anyone with a cellphone or any other portable electronic device. Lithium batteries are also used more and more in electric vehicles, which are becoming a global transportation trend, she said. She still has a long way to go before she reaches her end goal, but when she's successful, it will impact the lives of everyone whose cellphone battery always seems to die. "I want our electronic devices to last longer and charge faster," she said. | 9/16/2019 | September 2019 | | | 1. Headline |  | A revolutionary new cybersecurity tool that can help protect the electric power grid has been released to the public on the code-hosting website GitHub. Developed by researchers at the U.S. Department of Energy’s Idaho National Laboratory, the Structured Threat Intelligence Graph (STIG) software allows utility owners and operators to easily visualize, share, create, and edit cyberthreat intelligence information. The ability to share threat intelligence is essential for protecting critical infrastructure like the electric power grid, water treatment facilities, oil refineries, and manufacturing plants from cyber exploits. Prior to the development of this software, threat information was too complex and cumbersome to share, limiting its application in operational environments. The new software standardizes the collection via Structured Threat Information eXpression (STIX) and converts complex data on cybersecurity vulnerabilities into a visualization that is easy to understand and act on. With STIG, utility owners and operators have a common system for sharing threat intelligence information, thus increasing the chances of detecting and mitigating cyber exploits before they lead to a cyberattack. “We’ve been working on the development of this tool for quite a while and have had success testing it with a major utility,” said Jed Haile, INL cybersecurity researcher and tool developer. “This software helps analysts process new threat information rapidly and makes it easier for them to find or create relationships between pieces of information.” By releasing the open-source code on GitHub, INL researchers hope other developers will take on the challenge of making the tool even better and ultimately helping to better protect the nation’s critical infrastructure systems. In addition to Haile, INL Infrastructure Security Strategic Adviser Rita Foster and cybersecurity researchers Justin Cox and Zach Priest were instrumental in the tool’s development. The team has been working closely to test the software with Southern California Edison, a principal member of the California Energy Systems for the 21st Century (CES- 21) Program, and the primary electricity supply company for much of Southern California. The company provides 14 million people with electricity across a service territory of approximately 50,000 square miles. Southern California Edison sponsored the research that led to the development of the software. Seeing the potential for wider application of structured threat sharing, the California Public Utilities Commission approved a request to release the open-source code. The tool is available for free download at: https://github.com/idaholab/STIG | 9/16/2019 | September 2019 | | | 1. Headline |  | Three commercial electric utilities and Idaho National Laboratory have been chosen by the U.S. Department of Energy’s Office of Nuclear Energy’s funding opportunity announcement (FOA) U.S. Industry Opportunities for Advanced Nuclear Technology Development for a first-of-a-kind project to improve the long-term economic competitiveness of the nuclear power industry. Through this solicitation, DOE encourages partnerships between federal agencies, public and private laboratories, institutions of higher education, and the business community, including electric utilities, to share expertise needed to successfully develop innovative nuclear technologies. This project accomplishes DOE’s objective to support innovation in and competitiveness of the U.S. nuclear industry through research, development and demonstration of commercial applications that pair carbon-free nuclear energy in a hybrid, nonelectric application to produce hydrogen. The DOE awards announcement for this project and others can be found on the DOE website ( here). “This first-of-a-kind project represent significant advances for improving the long-term economic competitiveness of the light water reactor industry,” said Bruce Hallbert, director of DOE’s Light Water Reactor Sustainability Program, based at INL. “They will enable the production of commodities such as hydrogen in addition to electricity from commercial nuclear power plants. This project also accelerate the transition to a national hydrogen economy by contributing to the use of hydrogen as a storage medium for production of electricity, as a zero-emitting transportation fuel, or as a replacement for industrial processes that currently use carbon-emitting sources in hydrogen production.” The utility participants are Akron, Ohio-based FirstEnergy Solutions, the industry leader for the effort; Xcel Energy, a Minneapolis-based energy company that owns and operates two nuclear plants in Minnesota; and Arizona Public Service (APS), a Phoenix, Arizona-based utility that operates Palo Verde Generating Station. The two-year project led by FirstEnergy Solutions will initially demonstrate and deploy a 1- to 3-MWe low-temperature electrolysis unit to produce commercial quantities of hydrogen. The first site, planned for 2020, is FirstEnergy Solution’s Davis-Besse Nuclear Power Station near Toledo, Ohio. Hydrogen from Davis-Besse may initially be used to supply public transportation fleets in Ohio, in new direct iron reduction plants being constructed to produce steel products, or for other commercial products now under investigation. The project will demonstrate how hydrogen from commercial nuclear operations can be used to produce “green” products and commodities in significant quantities for domestic use and for export to international markets where green and low-carbon attributes are incentivized. “We are pleased to have been selected for this project by the Department of Energy and look forward to exploring the economic viability of H2 generation at a nuclear power plant, and demonstrating the compatibility and synergy of the two technologies,” said Raymond Lieb, senior vice president of Fleet Engineering for FirstEnergy Solutions. “Thanks to the support provided to our Ohio nuclear plants by the state of Ohio, we are able to work with DOE to explore new methods of keeping nuclear power plants competitive in any economic environment. This is a great opportunity to show that hydrogen can be effectively generated in a carbon-free and safe manner.” Xcel Energy will also participate in the demonstration project to help determine if hydrogen production can enhance the company’s growing carbon-free footprint. Redirecting nuclear energy from electricity to hydrogen production could help balance the electrical grid with the increasing amount of wind and solar energy on the system. The company has also been testing flexible operations at its nuclear plants, but hydrogen could create an entirely new value stream. Xcel Energy plans to reduce carbon emissions by 80 percent in the Upper Midwest by 2030 (from 2005 levels) and is pursuing a vision to provide electricity from 100 percent carbon-free sources by 2050. ”We’ve challenged our nuclear employees to find innovative ways to operate more efficiently, use technology, pursue new ideas and reduce costs to make our plants more valuable for our customers,” said Tim O’Connor, chief nuclear officer, Xcel Energy. “Projects like this hydrogen demonstration will ensure our nuclear plants continue to help Xcel Energy provide reliable, affordable carbon-free electricity for the Upper Midwest.” APS’ Palo Verde Generating Station near Phoenix, Arizona, also participates in the demonstration. Hydrogen from Palo Verde may be used as energy storage for use in reverse-operable electrolysis or peaking gas turbines during times of the day when photovoltaic solar energy sources are unavailable and energy reserves in the U.S. Southwest are low, and could also be used to support a burgeoning hydrogen transportation fuel market. Experience from this pilot project will offer valuable insights into methods for flexible transitions between electricity and hydrogen generation missions in solar-dominated electricity markets—and demonstrate how hydrogen may be used as energy storage to provide electricity during operating periods when solar is not available. “This project allows us to explore a new form of energy storage while continuing to provide customers what they want – clean, affordable and reliable electricity,” said Bob Bement, APS executive vice president and chief nuclear officer. “For more than 30 years, Palo Verde has been the largest single clean-air energy source in the country. This pilot combines advanced technology with existing infrastructure to integrate carbon-free nuclear power with the desert Southwest’s abundant solar energy. It is an exciting opportunity to advance a clean energy future for Arizona and beyond.” “This demonstration project will confirm how commercial nuclear utilities can produce—without carbon emissions—essential products, like hydrogen, at a scale needed by industry,” Hallbert said. “Nuclear energy can help meet the significant demand for hydrogen and other synthesized products while helping industrial users reduce their own carbon footprints.” | 9/16/2019 | September 2019 | | | 1. Headline |  | Idaho National Laboratory awarded prestigious INL Graduate Fellowships to 12 students from universities throughout the U.S. These students will become the third cohort of INL Graduate Fellows. Recipients of these competitive fellowships have their tuition and fees covered by their university during their first years of graduate school (years one to three). Their tuition and fees plus a $60,000 annual salary are paid by INL during the last two years of their doctoral research performed at the lab. In the first years of their Ph.D. program, graduate fellows will spend most of their time taking classes at their university. That balance will shift in the last years of their Ph.D. program, where graduate fellows will spend the majority of their time at INL conducting research. The typical graduate fellowship program runs between three and five years. There are mutual benefits for the graduate fellows, universities and the lab. Throughout the program, the graduate fellows will interact and collaborate with both their INL mentor and their university thesis adviser. The program allows INL to integrate students into the laboratory and provides graduate fellows with work on significant projects that will help them fulfill their thesis research requirements. INL gains access to skilled staff, along with the opportunity to build long-term collaborations with universities, increase recruiting opportunities, and interact with a continuous pipeline of students interning and conducting research at the lab. Both the university and INL have the opportunity for joint publications and intellectual property. “INL graduate fellowships offer huge opportunities for everyone involved,” said Michelle Thiel Bingham, INL’s University Partnerships director. “Universities gain a window into INL research, students are provided an amazing research experience while pursuing their education and INL researchers get fresh perspectives from the graduate fellows. The end result is the laboratory strengthens its partnerships with universities while continuing to develop the next generation.” Graduate fellows were selected in degree fields that closely tie to INL’s three mission areas of innovative nuclear energy solutions, other clean energy options and critical infrastructure. Congratulations to the following students who were selected as the third cohort of INL Graduate Fellows:  *N&HS: National & Homeland Security, NS&T: Nuclear Science & Technology, EES&T: Energy & Environment Science & Technology *N&HS: National & Homeland Security, NS&T: Nuclear Science & Technology, EES&T: Energy & Environment Science & TechnologyThe next call for graduate fellows will begin in fall 2019 and is open to all universities. For more information about the program, contact Ali Josephson (208-526-0940) or Michelle Thiel Bingham (208-526-7830) or visit inl.gov/education.*N&HS: National & Homeland Security, NS&T: Nuclear Science & Technology | 9/16/2019 | September 2019 | | | 1. Headline |  | By Erica Curless Dr. Yi Xie is the inaugural Glenn T. Seaborg Distinguished Postdoctoral Associate at Idaho National Laboratory (INL). Since starting her two-year appointment in August, Xie has conducted research at the Materials and Fuels Complex (MFC) using her background in the development and design of metallic fuels. Xie's research focuses on designing and fabricating advanced metallic fuels that eliminate the problem of fuel cladding chemical interaction (FCCI), which causes cladding failures that can jeopardize the safety of reactors. Cladding is the first safety shell for fuel inside a nuclear reactor. Xie said during burnup, which is fission in a reactor, lanthanides are produced as fission products. They can migrate to the fuel surface and diffuse with cladding, which results in the breach where fuel can leak into the coolants. She is developing advanced U-Zr and U-Pu-Zr metallic fuels that mitigate the lanthanide-induced FCCI problem when operating in the reactor, improving safety. "The research helps to reduce risks of incidents, and thus make the reactor more reliable," Xie said.

Xie's work with lanthanides fits the mission with the Glenn T. Seaborg Institute (GTSI) because its namesake co-discovered multiple elements, including plutonium, and committed his life's work to the advancement of actinide chemistry. Seaborg's research on lanthanides and actinides (also known as f-block elements) has had a huge impact on modern society. The mission of the GTSI at INL, launched in 2018, is to nurture talented researchers who have specific interest in actinide chemistry as it relates to basic science, the nuclear fuel cycle, reactor operation and engineering, waste minimization and treatment, and other technical fields. Xie also is the principal investigator for another project sponsored by INL's Laboratory-directed Research and Development (LDRD) program. The goal is to both improve the understanding of the retention capability of fission products in liquid sodium and to investigate the corrosion effects on structural materials inside a reactor, she said. This research is to help ensure the public and environment are protected from the potential release of radionuclides during normal and abnormal operations of reactors. With redundant safety systems present in a reactor, a radionuclide release is unlikely, but investigation is still needed to understand the consequences of a release, where the radionuclides go and how they react, Xie said. This research will help to solve the issues and gaps between limited mechanistic investigations of fission products release and the needs of an assessment. "Both projects ultimately improve reactor safety," Xie said. Since starting in August, Xie has published four papers on her research and is working on more publications for later this year. Xie, a native of southern China and a legal permanent resident of the United States, earned her doctorate in nuclear engineering at the Ohio State University and a bachelor's degree in nuclear engineering at University of Science and Technology of China. Prior to joining INL, she worked as a postdoctoral researcher at Virginia Polytechnic Institute and State University. Nuclear science piqued her interest as an undergrad when she attended many lectures and seminars before choosing nuclear engineering as her career path. Xie wanted to study in the United States to continue the advancement of nuclear science. This highly competitive postdoctoral appointment provides Xie with a structured environment centered on specific research topics while allowing flexibility to further her interests. The full support of the national laboratory, along with energetic and talented colleagues, offer an excellent opportunity for development of a rewarding career in this field. "This is a very good opportunity," Xie said. Working at a national laboratory is important because of the collaboration with the other researchers at the MFC, she said, especially mentor Dr. Michael Benson, a research scientist in Fuel and Experimental Assembly and Development. The distinguished postdoctoral appointment is a big bonus for early career research scientists. | 5/1/2019 | May 2019 | | | 1. Headline |  | From Marianne Walck, Science & Technology deputy laboratory director and National University Consortium director:

I am pleased to announce that Dayna Daubaras has been selected to serve as the deputy director of the National University Consortium (NUC) effective April 22. As the NUC deputy director, Dayna will work with the NUC's five research universities (Massachusetts Institute of Technology, North Carolina State University, the Ohio State University, Oregon State University and University of New Mexico) to continue to build and foster strategic partnerships between universities and INL researchers.

Dayna succeeds Marsha Bala, who has moved to a new position as the Nuclear Energy Innovative Capabilities Strategic Integration director on behalf of the DOE Office of Nuclear Energy. Marsha spent many years developing and championing NUC into a very impactful consortium. Please join me in thanking Marsha for her exceptional dedication and service.

The NUC deputy director is a part-time position. Dayna will continue in her current role as a staff scientist in the Chemical and Radiation Measurement department in Energy and Environment Science and Technology. Congratulations to both Dayna and Marsha on their new roles!

| 5/1/2019 | May 2019 | | | 1. Headline |  | Dr. Marianne Walck began her role as the deputy laboratory director for Science and Technology and INL's chief research officer on Jan. 7, 2019, replacing Kelly Beierschmitt who accepted a new role at Los Alamos National Laboratory.

Walck has more than 25 years of DOE National Laboratory technical leadership experience, including technical program leadership, research leadership, and line, personnel, and site management. From 2015 to 2017, Walck was the vice president of Sandia's California laboratory as well as serving as the lead for Sandia's Energy and Climate Program. As vice president of Sandia's California laboratory, Walck was responsible for principal programs including nuclear weapons stewardship; homeland security with a focus on defending against weapons of mass destruction; combustion, transportation, and hydrogen energy research; biology; and advanced computational and information systems.

Prior to that, Walck held a variety of research and management positions at Sandia. She served on the Sandia Research Leadership Team, created and led the Geoscience Research Foundation; was director of the Geoscience, Climate, and Consequence Effects Center; and was director of the Nuclear Energy and Global Security Technologies Center.

Walck received a master's and a doctorate in geophysics from the California Institute of Technology and a bachelor's degree in geology/physics from Hope College. She holds memberships in the American Geophysical Union, the Seismological Society of America, the Association for Women Geoscientists, the American Nuclear Society, and the American Association for the Advancement of Science. She serves on several advisory boards for universities and technical institutes including the Texas A&M Energy Institute, and is a Senior Fellow of the California Council of Science and Technology. | 1/21/2019 | January 2019 | | | 1. Headline |  | By Corey Taule History is rife with stories about unexpected opportunities: Teddy Roosevelt’s reformation presidency came about after an anarchist assassinated President William McKinley. Lou Gehrig’s 2,130 game streak resulted from a poor start to the season by the New York Yankees and the benching of first baseman Wally Pipp. And the Indiana Jones movies would have looked far different had Tom Selleck, the first choice, accepted the lead role. Though their ascensions could be considered accidental, Roosevelt, Gehrig and Harrison Ford were prepared when their moment arrived. They were the right men, in the right place, at the right time. As H. Jackson Brown Jr. wrote, “Opportunity dances with those already on the dance floor.” INL’s Dr. David Petti has spent nearly 40 years on the dance floor. Petti’s notable career began with an internship at INEL in 1980. Today, he finds himself at the center of the nuclear energy world – as the executive director on a high-profile Massachusetts Institute of Technology (MIT) study: “The Future of Nuclear Energy in a Carbon-Constrained World.” Petti earned his bachelor’s degree, master’s degree and Ph.D. from MIT. Following a long career at Idaho National Laboratory, opportunity arrived unexpectedly. Petti returned to his alma mater two years ago on a joint appointment, splitting his time between INL and MIT so he could lead the report. The MIT reportIn 2003, MIT, led by Ernest Moniz, who would later become U.S. Secretary of Energy under President Obama, released “The Future of Nuclear Power.” It was the first of MIT’s renowned “Future of” studies aimed at addressing complex issues involving energy and the environment. Future MIT studies addressed geothermal energy (2006), coal (2007), an update on nuclear power (2009), natural gas (2011), the nuclear fuel cycle (2011), the electric grid (2011), and solar energy (2015). Petti became involved in MIT’s ninth study after one of the original co-chairs died and another was promoted. When MIT’s Energy Initiative looked around, it discovered the right man, in the right place, at the right time. MIT released the report this month and Petti and his colleagues will discuss their findings at events in London, Paris, Brussels and Washington, D.C. An event in Tokyo will follow on Oct. 9. In the nuclear energy world, this is a big deal. “I can’t overstate the importance of the MIT reports in advancing the dialogue on nuclear energy,” said INL Director Mark Peters, who served as one of seven reviewers of the study. “INL is proud to have been a part of the process that resulted in this study, and we’re also very proud of Dave Petti’s work and distinguished career.” Past, present, futureThirty-eight years ago, INL was INEL, Mount St. Helens erupted, CNN launched, John Lennon was murdered, the U.S. defeated the Soviet Union in the “Miracle on Ice,” the Reagan era was soon to begin, and Dave Petti began what would become his life’s work. Petti interned at INL for several summers before joining full time in 1986, embarking upon a professional journey that would see him become expert in many aspects of nuclear energy research and development, and leave him well prepared for his unexpected assignment at MIT. Petti studied severe accidents, focusing on Three Mile Island not long after it took place, gas reactors, fusion safety and nuclear fuel. He was co-National Technical Director of the U.S. Department of Energy’s Advanced Reactor Program. It all added up to Petti becoming one of the few people to begin their careers at INL as an intern and earn the status of INL Laboratory Fellow. “He is a very big figure in all this,” said John Wagner, Associate Laboratory Director for Nuclear Science and Technology. “Think about his contributions, what a force he’s been. He’s one of those guys, when he talks, people stop and listen.” Like everyone involved in nuclear energy, Petti has experienced highs and lows – the inevitable recession lurking behind the anticipated renaissance. The MIT study, and the work involved in making it possible, offered Petti an opportunity to impact the future, address issues impeding an expansion of low-carbon nuclear energy, and offer recommendations to policymakers and industry. The bottom line, Petti said, is the need for greater awareness that demand for energy will increase an estimated 40 percent by 2050, and the only way to meet it and reduce carbon emissions is to build thousands of advanced nuclear reactors around the world. “To decarbonize, we’re going to need a lot of reactors,” Petti said. “One of the big reasons to do nuclear is decarbonization.” Petti said recent bankruptcies and shuttering of nuclear power plant projects in Georgia and South Carolina caused the MIT group to focus even more on cost, and deliver recommendations centered upon reducing them. Those include two of potential interest to INL: establishment of reactor sites “where companies can deploy prototype reactors for testing and operations orientated to regulatory licensing;” and establishment of funding programs “around prototype testing and commercial deployment of advanced reactor designs …” One of the most enlightening aspects of the study looked at decarbonization models, and the belief that the world can meet future energy demands and carbon-reduction goals using a combination of solar, wind and battery storage. Petti and his colleagues looked at models centered in Texas and New England, factoring in anticipated weather conditions for an entire year. What did they find? “The answer is ‘maybe,”’ Petti said about the wind, solar and storage question, “but the cost would be astronomical. Bring nuclear into the mix and the costs go down.” Petti said he is proud of the nearly 300-page document he and his team produced, and hopes it will inspire serious discussions at statehouses around the country and on Capitol Hill. “I see it as a capstone,” Petti said. “What an opportunity to effect the nuclear debate on the international level.” | 9/30/2018 | October 2018 | | | 1. Headline |  | By Misty Benjamin and Tabrie Cook Leading the way in securing our nation's energy future, Idaho National Laboratory, together with the Idaho State Board of Education, is breaking ground on two new research facilities: the Cybercore Integration Center and the Collaborative Computing Center (C3). On Wednesday, April 11, key stakeholders and elected officials celebrated the beginning of a strategic partnership to advance research and educational collaboration in Idaho. "Supporting this collaboration is about much more than new facilities; we are investing in Idaho's future," Idaho Governor C.L. "Butch" Otter said. "The Lab is a major employer in its own right and has a global reputation that benefits many other Idaho businesses. But in addition to the INL's continuing economic importance, this partnership provides Idaho universities with an important edge in preparing tomorrow's world leaders in cybersecurity and nuclear energy research." Cybercore Integration Center will host advanced electronics labs for industry, government and academia to work together to systematically engineer cyber and physical security innovations to protect the nation's most critical infrastructure, like the power grid. The Collaborative Computing Center will provide a modern computing environment, hosting research collaborations and opportunities that would otherwise not be possible – a place where INL researchers, Idaho universities, and industry will explore computer modeling and simulation to develop new nuclear materials, advance nuclear energy concepts and conduct a broad span of scientific research. "We are working with Idaho's universities to strengthen partnerships, for example, by tailoring internships for students seeking advanced degrees in nuclear engineering, mechanical engineering, materials science, chemical engineering and computer science," INL Director Mark Peters said. "Students are the talent of the future, and we want to invest in their success. By offering these career-enhancing opportunities, everyone wins." Idaho State Board of Education will retain the economic benefit that will be created by the financing, construction, and operation of these facilities. This endeavor enables educational opportunities, globally significant research, and economic opportunity. Off-site computer users, such as students and faculty at Idaho's universities and colleges, will also have remote access to the high-performance computing systems in the Collaborative Computing Center through the Idaho Regional Optical Network (IRON). "We are positioned for the future. This is an exceptional example of a public/private partnership working to advance the educational offerings across the entire state," said Dr. Linda Clark, president of the Idaho State Board of Education. "We are excited about the opportunities this provides for all of Idaho's institutions of higher learning." | 6/4/2018 | June 2018 | | | 1. Headline |  | For most working in the field of nuclear energy, the American Nuclear Society conferences are frequently attended to learn about the latest innovations, present their newest research, and spark new hypotheses. But the best ideas aren't always found in the lecture halls. In the case of the latest collaboration between Idaho National Laboratory and Oregon State University, lunchtime was the breeding ground for innovation. "Like many good things, I recall that this idea was hatched over lunch at an ANS conference a few years ago," said Mitch Meyer, the Characterization and Advanced Post-Irradiation Examination director. The course entitled "Nuclear Fuel Qualification – Post Irradiation Examination" was taught by Meyer and 11 other INL researchers with Wade Marcum, an associate professor at Oregon State University, facilitating the course. This inaugural class had 16 students, but faculty members also sat in during many lectures. "There was a lot of curiosity about the topics we were presenting," Meyer said. Mitch Meyer The unique course covered topics such as fission gas measurement, electron beam characterization and fuel performance codes. "The faculty and university very much appreciated this exchange and opportunity as it fills a gap in the present teaching curriculum and connects us with a premier research institute in a way that we have not before," Marcum said.

Finding volunteers at INL to teach the course wasn't difficult for Meyer, and he ended up with more volunteers than sections to teach. Aaron Craft, who taught the lectures on neutron radiography, attributes this to the passion scientists have for their work. "Scientists like talking about what they do. Since they're the subject matter experts, they can talk about it in more detail and in more breadth," Craft said. To continue to fulfill INL's mission of demonstrating nuclear energy as the cleanest and most reliable form of energy, Craft believes this sort of interaction is key to inspiring the future wave of nuclear engineers. "We have to be advocates for our science in the public as well, which includes classrooms teaching the next generation of students."

After building the curriculum through a series of conference calls with Marcum, discussions with INL researchers, several hours of work on nights and weekends, and approval of the Oregon State nuclear engineering faculty, the class was taught by INL researchers both in person and via video conferencing. Overall, the class was well received by the students. "The comments that I personally received were that they enjoyed the course subject matter," Marcum said. "But mostly they appreciated the insightful topical delivery that could only be provided by a national or international topical expert on that subject matter."

"No other university provides this type of course," Craft said. "When we get bright nuclear engineers or materials scientists in here, they haven't had an education on post-irradiation examination or nuclear fuel qualification anywhere. It doesn't exist, so we end up teaching them from scratch."

Although the idea for the course began over a meal, the collaboration is one of the many that have occurred as part of INL's longstanding partnership with the university through its National University Consortium. Established in 2005, the NUC is a partnership between INL and five prominent research universities, Massachusetts Institute of Technology, North Carolina State University, the Ohio State University, the University of New Mexico and Oregon State University.

The lasting impact of the most recent collaboration between INL and Oregon State University is already being felt. Meyer plans to host a few interns from the university this summer; Craft has already been contacted by graduate students to run experiments at the Neutron Radiography Reactor that he works with; Craft also plans to host a faculty seminar at INL and assist Oregon State with their camera-based imaging system at their nuclear reactor; and Meyer is hoping this course will be the first of many: "I'm already thinking about the next one."

| 3/5/2018 | March 2018 | | | 1. Headline |  | In September 2017, Idaho National Laboratory announced its first group of 11 INL graduate fellows. Three months later, the first two students, Casey Icenhour and Konor Frick, were accepted to Ph.D. candidacy and arrived in Idaho Falls to begin their work with INL.

A collaboration between INL and universities, INL's Graduate Fellowship program is aimed at identifying exceptional talent to continue INL's mission of demonstrating nuclear energy as the cleanest and most reliable energy source. The program is also built to offer mentoring and financial support to students beginning or currently enrolled in Ph.D. programs. During the first years of their doctoral programs, students spend their time at their universities completing coursework while collaborating with their INL mentor and Ph.D. adviser to develop a research plan. Once coursework is completed, graduate fellows spend the last years of their Ph.D. program at INL conducting research as outlined in their research plan.

Frick and Icenhour, both from North Carolina State University, began the second portion of their fellowship earlier this year, relocating full-time to Idaho Falls to complete their doctoral research. Frick finished his Ph.D. program shortly after arriving in Idaho, successfully defending his dissertation in nuclear hybrid energy systems at the end of January.

Icenhour is still currently pursuing a Ph.D. in nuclear engineering and spent the last year-and-a-half at Oak Ridge National Laboratory through the Office of Science's Graduate Student Research Program. Before hearing about its INL Graduate Fellowship program, outside of INL's general mission, Icenhour wasn't very familiar with INL. However, through another NCSU student, Alex Lindsey, who had worked with INL previously and is now an employee, Icenhour and his Ph.D. adviser, Steve Shannon, saw a valuable connection between his thesis topic and the modeling and simulation work—i.e., Multiphysics Object Oriented Simulation Environment (MOOSE)—being done at INL. Currently, Icenhour is working on expanding the MOOSE framework to include his work on electromagnetic wave propagation. "It's been a boon to my work because instead of just focusing on that and only that, I'm starting to think more about the applications of my research," he said.

Rich Martineau, Icenhour's INL mentor, sees the benefits for everyone involved. For the students, Martineau gives "top-flight mentoring during the graduate research phase" to make sure that that they get the maximum benefit out of "a couple of their best years of research." Martineau recognizes the level of responsibility INL mentors have in order to make sure this is a positive experience for the incoming students. His advice to INL mentors? Challenge the students. "The only thing that matters here is that Casey is successful."

Although his time at INL has been short, Icenhour also has advice for other INL graduate fellows who will be arriving in Idaho Falls in the months and years ahead. "You need to be willing to step outside your group and be willing to engage with other researchers."

He noted that being at a national laboratory is very different from academia. "The folks around here are working on a broader class of problems," Icenhour said. As a Ph.D. student studying a very specific area, he said it can be a "culture shock." But he thinks this ultimately benefits students. "It makes you, as a grad student, a better researcher."

Frick also has advice for students once they get to INL: Have a detailed research plan. "The goal of this program is to have students earn their Ph.D.," Frick said. "Create a well-outlined research plan with your INL mentor and Ph.D. adviser to make sure all parties agree the research done at INL enables that to happen."

As the program continues to grow, Michelle Bingham, University Partnerships director, sees the INL Graduate Fellowship program filling the talent pipeline and continuing to bring in qualified employees already familiar with the work being done at INL. She also envisions this already-competitive program becoming even more familiar across the country. "Over time, the INL Graduate Fellowship will become a well-known, prestigious program that students vigorously pursue in order to differentiate them from their peers," Bingham said.

For more information about the INL Graduate Fellowship program and other student opportunities at INL, contact internships@inl.gov or visit inl.gov/gradfellows.

| 3/5/2018 | March 2018 | | | 1. Headline |  | By: Paul Menser For an idea of how researchers at Idaho National Laboratory envision the power distribution system of the future, take a look at large information distribution systems: the internet, of course, but perhaps telephone communications even more. At the beginning of the 20th century, telecoms were small and highly localized. By mid-century, the nationwide Bell System had evolved, but an overseas call would still cost a bundle. Today, inexpensive intercontinental telecommunications are the norm. In September, a group of INL researchers hosted a live demonstration of the Global Real-Time Super Lab, linking three national labs and five universities in the United States and Europe for a simulation to study how electricity can be distributed across vast distances to maintain stability and address disruptions. The concept is to distribute electrons over transmission wires the same way digital packets of zeros and ones are sent over the internet. Power systems around the world are undergoing fundamental transitions to achieve long-term sustainability, reliability and affordability. The ability to move electricity around the globe rather than only within isolated networks holds the possibility of vast savings on infrastructure and energy consumption. Starting around 10:30 a.m., researchers from Idaho Falls to Albuquerque, New Mexico, to Columbia, South Carolina, to Aachen, Germany, and Turin, Italy, began linking their grid research systems. Numerous partners contributed real-time simulators that simulate how large-scale electricity systems act in the real world. Contributions also included simulated diverse set of energy sources and components such as wind energy, solar energy, storage systems, microgrids, and dozens of electric vehicles. Then, the team ran a simulated disruption based on a natural disaster such as hurricane to assess how the power grid can be stabilized. "We hit a home run today," said Rob Hovsapian, manager for INL's Energy Systems & Technologies Division. "This gives us global credibility." In addition to having DOE officials for an audience, the demonstration was seen in Torino by participants at IEEE's Innovative Smart Grid Technologies conference (ISGT-Europe). The demonstration was the culmination of four years of work that dates back to joint research between INL and the U.S. Department of Energy's National Renewable Energy Laboratory (NREL) in Golden, Colorado. Researchers at Sandia National Laboratories and five universities joined INL to explore the idea that electrons can be sent around the world to prevent large-scale blackouts that could be caused by natural and man-made disasters. Participants contributed specific capabilities: Sandia National Laboratories: Distributed Energy Technologies Laboratory Colorado State University: High-performance computer-based energy management system Washington State University: Smart Grid and Microgrid Laboratory University of South Carolina: Integrated Grids Laboratory (InteGraL) RWTH Aachen University: Co-simulation framework Polytechnic University of Turin: High-performance computer-based Energy Management System NREL: Energy Systems Integration Facility INL: Power and Energy Real-Time Laboratory

Beyond the obvious benefits of connecting technology, the project brings people from across the country and around the globe onto the same team. In addition to the several papers they have published, Marija Stevic, a graduate student at RWTH Aachen, is using the project to support her doctoral dissertation. Stevic benefited from a "12-month Ph.D. internship" program that allowed her to spend more than a year at INL contributing to the research program. The RT Super Lab will provide a platform for other participants to pursue similar long-term exchange activities. "We are hoping this is a game-changer," said INL's Manish Mohanpurkar, group lead of the energy systems research group. Each lab that participated in the demonstration funded its own participation, and INL's portion was part of an internally funded Lab-Directed Research & Development project. With connections firmly established between the participants, the continued sharing of information and resources will allow researchers to learn more about such issues as data latency and instability. Building on what was learned at the first RT-Super Lab demonstration, Hovsapian said he is hopeful that partnering laboratories in Asia, South America and Australia may eventually opt in. | 12/4/2017 | December 2017 | | | 1. Headline |  | On Tuesday, November 14, Idaho National Laboratory (INL) achieved an important step towards restoring U.S. nuclear energy transient testing capability with the resumption of operations at the Transient Reactor Test (TREAT) Facility. The TREAT facility has been shut down and maintained in standby status since 1994. TREAT is designed specifically to test nuclear reactor fuels and materials under extreme conditions. It can produce sudden bursts of energy that are more than five times more powerful than a commercial power plant—allowing scientists to examine fuel performance. This capability is an important asset to nuclear scientists and engineers as they work to increase the safety and performance of current and future nuclear reactors. "The Department of Energy's decision to restore transient testing capability at INL is part of our efforts to revitalize the nation's nuclear energy capacity," said Ed McGinnis, Principal Deputy Assistant Secretary for Nuclear Energy. "By investing in innovative fuel cycle infrastructure, we can advance nuclear as a key source of clean, resilient power and maintain U.S. leadership in developing advanced nuclear technologies." INL restored the TREAT reactor to operational status after the successful completion of extensive inspection and refurbishment activities over the last few years, thorough evaluation and assessment of reactor systems, and the low-power run conducted today. "The successful resumption of TREAT operations was the result of the effort of many people within INL and DOE," said INL Laboratory Director Mark Peters. "This teamwork resulted in resumption of operations being accomplished 12 months ahead of schedule and for nearly $20 million less than originally estimated." Over the next several months, INL will prepare for reactor transient operations and performance of the first new transient experiments in 2018. | 12/4/2017 | December 2017 | | | 1. Headline |  | By: Leslie Wright Idaho National Laboratory researchers are racking up accolades for the new technology they develop. This summer, two more honors were added to the list. First, INL received honors at the Idaho Genius Awards, ranking in the top five Idaho companies by number of patents issued. Battelle Energy Alliance, which operates INL on behalf of the U.S. Department of Energy, ranked fourth in the state for over two dozen issued patents. Joining BEA in the top five were Micron, Hewlett-Packard Development, Semiconductor Components and the Intel Corporation. Since BEA's contract to manage INL began, applications have been filed for over 472 patents, with more than 450 issued. In the 2016 fiscal year alone, 30 patents were issued to both INL and DOE based on the inventions of INL employees. Products, processes and innovations protected by INL patents and copyrights generate tens of millions of dollars annually in revenue for U.S. businesses. One such new technology is the General Line Ampacity State Solver (GLASS), which was selected as a 2017 R&D 100 Award finalist. The R&D 100 Awards recognize the top 100 inventions each year, as judged by a panel of independent experts. The annual conference also celebrates innovation and revolutionary ideas in science and technology. GLASS is a software package designed to help power line operators manage transmission for maximum efficiency and savings by calculating weather effects on lines. The java-based software incorporates wind and other weather data from remote sensors and then calculates the cooling effect of this phenomena on individual sections of line. This information, based on real-time data, enables dynamic control going beyond typical Static Line Ratings, which use a fixed set of environmental conditions. GLASS allows system planners and grid operators to better direct current over lines without the risk of overheating and enables utility companies to adjust power production and manage fluctuations in load more effectively.

INL nominates technologies to the R&D 100 Award competition nearly every year, and the lab has collectively won 18 awards since 2005. This year's R&D 100 winners will be announced at an awards dinner in November. Congratulations to the GLASS team and power systems engineer Jake Gentle, who led development of the software package funded by DOE's Wind Energy Technologies Office.

These honors also follow on the heels of three INL wins of Far West Regional Awards granted by the Federal Laboratory Consortium.

| 10/9/2017 | October 2017 | | | 1. Headline |  | Effective October 1, Dr. John Wagner is the new associate laboratory director for Nuclear Science & Technology (NS&T). Kemal Pasamehmetoglu, former NS&T Director, has accepted a new position at INL as executive director of the Versatile Fast Neutron Source Research & Development Initiative. Before his new position, Wagner was the director of Domestic Programs for INL's NS&T directorate and director of the Technical Integration Office for the DOE-NE Light Water Reactor Sustainability (LWRS) Program. In these roles, he has provided strategic coordination at INL for the major DOE-NE programs, led the Advanced Nuclear Energy area of INL's LDRD program, and transitioned the LWRS Program from an emphasis on Subsequent License Renewal to reduced operating costs and modernization of the LWR fleet. Wagner previously served at INL as chief scientist for the Materials and Fuels Complex, where he was responsible for implementing strategies to modernize the MFC research and development capabilities. His contributions helped to transform MFC to a more effective nuclear energy R&D organization, fostered collaborations with nuclear universities and laboratories, and facilitated delivery of outcomes for industrial partnerships to meet fuels and materials research and development needs. He has more than 20 years of experience performing research, and managing and leading research and development projects, programs, and organizations. Prior to joining INL nearly two years ago, he worked at Oak Ridge National Laboratory for nearly 17 years, where he held a number of research and leadership roles in reactor and fuel cycle technologies. John received a bachelor's degree in nuclear engineering from the Missouri University of Science and Technology, and master's and doctorate degrees from the Pennsylvania State University. He is a Fellow of the American Nuclear Society and recipient of the 2013 E. O. Lawrence Award. He has also authored or co-authored more than 170 refereed journal and conference articles, technical reports, and conference summaries. | 10/9/2017 | October 2017 | | | 1. Headline |  | Congratulations to the National University Consortium (NUC) research teams who won Consolidated Innovative Nuclear Research awards beginning in FY 2018. - An Experimental and Analytical

Investigation into Critical Heat Flux (CHF) Implications for Accident Tolerant

Fuel (ATF) Concepts: Researchers will develop a

holistic best estimate assessment of the potential impact of different ATF

cladding materials with regards to heat transfer characteristics, the boiling

curve, critical heat flux, fuel mass/volume/specific power density, and

neutronics effects due to changes in the lattice design or parasitic neutron absorption

during design basis accident conditions in light water reactors.

- Collaborators:

- PI: Youho Lee (University of New Mexico)

- Edward Blandford

(University of New Mexico)

- Nicholas R. Brown (Pennsylvania State University)

- Wade Marcum (Oregon State University)

- Simon Walker, Geoffrey Hewitt, Radd Issa (Imperial College London)

- Colby Jensen (Idaho National Laboratory)

- John Strumpell (Areva)

- Raul Rebak (General Electric Global Research)

- Combined modeling and experiments

to predict corrosion and embrittlement in dual-phase stainless steels within

the MARMOT framework: Researchers will enhance

MARMOT to predict mechanical and corrosion properties of dual-phase stainless

steels as a function of composition, aging time and temperature by using

combined experimental data and lower length scale models.

- Collaborators:

- PI: Julie Tucker (Oregon State University)

- Dr. Liney Arnadottir, Dr. Burkan Isgor (Oregon State University)

- Dr. Yongfeng Zhang (Idaho National Laboratory)

- Integrating Static PRA

Information with RISMC Simulation Methods: Researchers will develop a

computationally feasible and user friendly process to augment the traditional

probabilistic risk assessment (PRA) results with improved representation of

epistemic uncertainties and process/hardware/software/human interactions at

plant level applications.

- Collaborators

- PI: Tunc Aldemir (The Ohio State University)

- Dr. Yassin Hassan (Texas A&M University)

- Dr. Andrea Alfonsi (Idaho National Laboratory)

- Dr. Askin Yigitoglu (Oak Ridge National Laboratory)

NUC faculty members and Idaho National Laboratory scientists will also be collaborating on the following projects. - Development of Information

Trustworthiness and Integrity Algorithms for Cybersecurity Defenses of Nuclear

Power Plants: Researchers will develop a

first-of-a-kind physics-based defense-in-depth strategy to defend against false

data injection attacks which attempt to change the information used by the I/C

network to set reactor state. The approach employs a new design philosophy to

check for information trustworthiness/integrity in order to determine whether

the information is genuinely generated during the actual operation of the

nuclear unit under either normal or off-normal conditions

- Collaborators:

- PI: Hany S. Abdel-Khalik (Purdue University)

- Dr. Elisa Bertino (Purdue University)

- Dr. Ayman Hawari (North Carolina State University)

- Dr. Katrina Groth (Sandia National Laboratory)

- Dr. Virginia Wright (Idaho National Laboratory)

- Modeling of Spent Fuel

Cladding in Storage and Transportation Environments: Researchers will advance

the technical state of compact heat exchangers and lay the foundation to get

these types of heat exchangers certified for use in nuclear service. The team

will advance the understanding of the performance, integrity and lifetime of

the CHXs for use in any industrial application. This will be done by developing

qualification and inspection procedures that utilize non-destructive evaluation

(NDE) and advanced in-service inspection techniques, with insight from EPRI.

- Collaborators:

- PI: Arthur Motta

- Nicholas Brown, Long Quing Chen, Daniel Koss, Robert Kuz, Michael Tonk (Pennsylvania State University)

- Mohammed Zikry (North Carolina State University)

- Thomas Downar, Annalisa Manera, Victor Petrov, Volkan Seker (University of Michigan)

- Brian Wirth (University of Tennessee)

- Giovanni Pastore (Idaho National Laboratory)

- Kurt Terrani, Mahmut Nedim, Cinbiz (Oak Ridge National Laboratory)

- Carlos Tome (Los Alamos National Laboratory)

- Zeses Karoutas, David Mitchell, Javier Romero (Westinghouse Electric Corporation)

- Mark Kaymond (Queens University)

| 10/9/2017 | October 2017 | | | 1. Headline |  | U.S. Secretary of Energy Rick Perry spoke Tuesday afternoon to Idaho National Laboratory employees in a packed hall at the lab's Idaho Falls campus. The speech capped Perry's two-day tour of INL facilities, which included briefings on nuclear power and its effects on energy, national security and the environment. During his speech Perry touted the U.S. Department of Energy; he said that although the governorship of Texas has been his favorite position thus far, the "coolest" job of his career has been that of energy secretary. It was Perry's first visit to INL. This week's visit is the first of several planned lab visits for Perry. While addressing INL employees, he discussed the importance of national labs in science, economics and domestic security. "I cannot tell you how honored I am to be associated with men and women who do what you do, who truly have the potential to change the world on any given day," Perry said. "We have the national labs that are going out there and scientifically experimenting and finding the next big thing, and you all are at the heart of that." After his speech, Perry threw his support behind INL as a flagship lab within the DOE complex, particularly in nuclear research. "What Idaho does is at the top of the list from my perspective, and I'll say that tomorrow when I go to (Los Alamos National Laboratory) as well," Perry said, reiterating that INL is "going to be one of the lead players, if not the lead player, as we develop and are developing the nuclear energy portfolio." He specifically mentioned nuclear within weapons, security and energy contexts. Many in the nuclear field believe the U.S. is trailing other countries, particularly China and Russia, in the development of next-generation advanced nuclear reactor technologies. Perry mentioned the importance of catching up. "Because in the last 30 years, the fact is we got behind in this country," he said. "And you and young people you're going to recruit to come in here over the course of the next decade or so have the potential to change that trajectory in a very powerful and positive way." Part of that, Perry said, involves making nuclear attractive to the next generation — "making nuclear energy cool again" — and part of it involves embracing new technology. Perry specifically referenced fast reactor technology. The DOE is undergoing a three-year research and development process regarding a potential fast-neutron test reactor at INL's desert site. The research follows DOE and Nuclear Energy Advisory Committee reports published late last year and early this year, respectively, that both recommend developing a fast reactor in the U.S. "The U.S., I think, would be wise to use the resources we have here to commit to having the ability to participate in that fast reactor technology and the potential it has for the future," Perry said. He also spoke of the importance of modernizing decades-old INL infrastructure. A spending package signed into law last week by President Donald Trump includes $238 million for INL infrastructure maintenance and improvement. Though nuclear has been and remain's INL's primary mission, Perry also discussed the importance of embracing other research areas, including cybersecurity and supercomputing. The state Legislature approved a resolution this year allowing $90 million in state bonds to be used in the construction of two INL buildings in Idaho Falls. One of them, the Cybercore Integration Center, will play a key role in cybersecurity research, which is one of INL's fastest-growing departments. The other, the Collaborative Computing Center, will house a new supercomputer to be used for scientific simulation and modeling. "I think it's an opportunity for the state of Idaho to be world-leading," INL Director Mark Peters told the House Education Committee in March. Cybersecurity research and supercomputing capabilities are national security focal points for the Trump administration, Perry said. "We're not where we need to be from a cybersecurity standpoint; we're no longer number one in supercomputing. And that is of great concern to me. It should of great concern to the people of this country. I certainly am confident the president shares this concern," he said. "Exascale computing," an upcoming major step in computer engineering, "the next generation of supercomputers — both of those are growth areas, and I'd suggest to you the future of both of those will be prioritized." Perry also referenced the importance of other INL ventures — everything from biofuel research to M1 Abrams tank armor manufacturing — and how such work affects lives in the U.S. and abroad every day. "You get to do some stuff that waters people's eyes," Perry said. "When you leave here and go home, and you look in the mirror at night, you don't have to worry nor wonder whether you make a difference. You do, and I'm proud to be on your team."

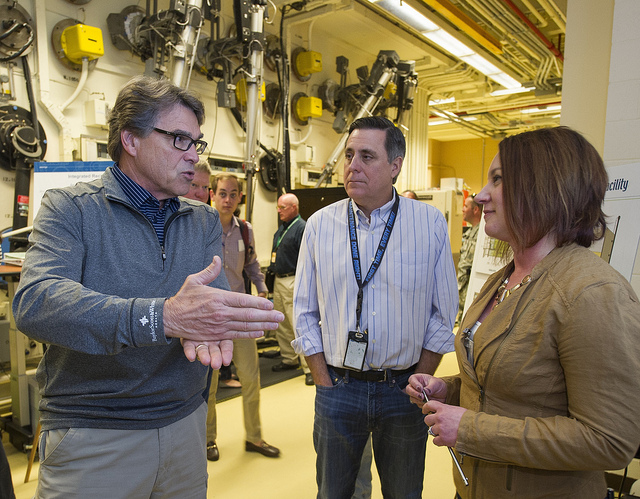

By: Kevin Trevellyan with the Post Register

| 6/5/2017 | June 2017 | | | 1. Headline |  | The American Nuclear Society recently recognized the Idaho National Laboratory’s Advanced Test Reactor (ATR) Complex as a Nuclear Historic Landmark at the 2016 ANS Winter meeting in Las Vegas. On May 18, ANS President Andy Klein presented the award during a visit to the ATR Complex.

The designation recognizes not only the contributions of the ATR, but also its predecessor reactors: the Materials Testing Reactor (MTR), Engineering Test Reactor (ETR), Engineering Test Reactor Critical, Advanced Test Reactor Critical, and Advanced Reactivity Measurements Facility I and II, as well as the hot cells, Radiation Measurements Laboratory and other research capabilities that have resided at ATR Complex throughout the years.

MTR began the legacy of materials testing at the ATR Complex when it achieved criticality, or in more simple terms began operating, in March 1952. It was a 30-megawatt (Mw) reactor that, after operating experience, was increased to operate at up to 40 Mw, with irradiation positions outside of the core. These positions allowed scientists to expose experiments to both neutron and gamma radiation at an accelerated rate. It began testing fuels and structural materials for other reactors, but was limited by the ability to only expose one side of an experiment to the nuclear environment. Changes were made and experiments were safely inserted into the core of MTR for a better irradiation environment. MTR also has the distinction of being the first light-water reactor to operate using plutonium fuel.

The Engineering Test Reactor, rated at 175 Mw, achieved criticality in September 1957. Learning from experiences at MTR, ETR was built with regular, in-core experiment positions and was able to more efficiently and quickly irradiate experiments for customers. In the latter stages of ETR’s life, it had a sodium-cooled loop passing through the core to support liquid-metal-cooled reactor designs.

The ATR took over a bulk of the materials testing being done at the ATR Complex when it achieved full-power operations in 1969 after initial criticality in July 1967. ATR is capable of 250 Mw operations. Building on what was learned in MTR and ETR, ATR made use of a revolutionary core design in which the fuel was arranged in a “serpentine” fashion. The new design allowed five in-core experiment positions surrounded by fuel and four out-of-core positions with fuel around half of the experiment area. A number of other test positions throughout the beryllium reflector exist for experiments of varying sizes and needs. In total, 77 test locations are available in ATR.

Other improvements made when ATR was designed and constructed include nine pressurized water loops passing through the core; these positions provide a physical environment to match power plant temperature, pressure and chemistry while ATR accelerates the nuclear conditions. As missions have changed over the years, three of the pressurized water loops have been removed, and six are now available. ETR had similar capabilities, but not nearly to the extent built into ATR. The designers also understood the need to replace structural material in their own test reactor, and ATR has undergone regular Core Internal Changeouts (CICs). There have been five CICs so far, with the next being planned for early 2020. ATR has the capability to operate regions of the reactor at different power levels, meeting the specific needs of different customers all at the same time.

MTR operated until April 1970, and ETR until December 1981. During a short period, all three reactors were irradiating fuels and materials for a number of customers. Since 1981, ATR has been utilized as the irradiation choice for Naval Nuclear Propulsion, commercial and test reactor designers, next-generation nuclear designers and other countries. In 2007, it was designated a National Scientific User Facility, since renamed the Nuclear Science User Facilities, attracting university and industry experiments from across the nation.

On Thursday, June 29, an anniversary celebration will be held at ATR Complex to mark 50 years of safe operations. ATR is currently completing a number of replacements and upgrades throughout the plant in anticipation of many more years of irradiation service to nuclear researchers from around the U.S. and the world.

By: Don Miley

| 6/5/2017 | June 2017 | | | 2. Research |  | Collaborations between Idaho National Laboratory and prominent universities are advancing the science and development of next generation nuclear energy technology with recently awarded projects that include efforts important to the conceptual design for a proposed, one-of-a-kind research reactor.

INL's National University Consortium (NUC) was established in 2005 and allows INL and the five participating universities – Massachusetts Institute of Technology, Oregon State University, North Carolina State University, The Ohio State University and University of New Mexico – to provide cutting-edge research that wouldn't be possible by either the lab or the universities individually.

"NUC is a win for both the lab and the universities because it increases impactful science and technology," said Marianne Walck, who oversees the NUC as its director and serves as INL's deputy laboratory director for Science and Technology and chief research officer.

Several projects awarded within the last six months have both INL and NUC university team members. Projects focus on a wide range of nuclear energy research from a first-of-a-kind modern autonomous control framework for a nuclear reactor to developing novel nickel-ODS alloys for use in next generation molten salt reactors, to research supporting the creation of the proposed Versatile Test Reactor (VTR).

The U.S. Department of Energy (DOE) Office of Nuclear Energy established the VTR program in 2018 in response to studies indicating a need for a U.S.-based research reactor to produce neutrons at higher energies to support development of new nuclear energy technologies.

Two of the VTR supporting projects are led by researchers at the MIT Nuclear Reactor Laboratory (NRL). One project is focused on data infrastructure of the proposed VTR while the other evaluates containment systems for gases that might result from various types of high-temperature salt experiments in the test reactor. These university-led projects are part of mixed university-industry teams such as the MIT Hierarchical Data Format (HDF) Group, a nonprofit organization developing data management technologies.

David Carpenter, group leader for reactor experiments at the NRL, is the principal investigator on the data project and involved with gas control system research. He said many universities, national laboratories, and industry partners are working together on small aspects of the VTR. The goal is to build a one-of-a-kind research reactor that would generate high-energy, or "fast," neutrons for experimentation and testing purposes. This requires input from the U.S. nuclear science and engineering research community.

"It's a smart matching of capabilities and research," Carpenter said about the projects. He said the partnerships are a nice blend of practical industries with the academic world, which doesn't always happen.

The data project will initiate the creation of a unified information network for the test reactor, which not only manages the internal reactor controls but also delivers experimental data, converting it to a format to be shared across a network for diverse users.

MIT's role focuses more on the actual hardware used to digitize raw signals and turn them into data. Other members of the data team are working on ways to take the wide arrays of data and convert the information to share on the network at high speeds.

"My part is someone will give me output from 100 thermocouples, and then we'll take all that and pass it into the computer in a smart way," Carpenter said.

The gas control project looks at the challenges and needs to get gases transported through various types of salt experiments that are inserted into the VTR. This is part of the initial reactor design work looking at the fundamentals of what type of space and equipment configurations are needed.

The hope for these one-year projects is they will be renewed and the VTR work will continue to progress to where actual experiments begin. Carpenter said that will save time and money because new teams won't have to start over each year, which would make it easier to involve students in ongoing projects.

"This is great if students can contribute to a new reactor in the U.S.," Carpenter said. "It's a huge deal and a monumental task. It's really tantalizing."

Other important work funded by NUC awards includes that of Michael Glazoff, an INL distinguished staff scientist. Glazoff is collaborating with an international team of researchers to develop and examine new ODS-strengthened superalloys that can withstand the detrimental effects of neutron radiation and hot corrosion in a molten salt reactor for longer periods of time as required in the new generation of nuclear reactors.

North Carolina State University is the lead on the project that includes the University of Idaho, University of California-Berkeley and Oxford University.

The team is using yttria Y203 as the oxide with the hope of creating a material with the strength of the corresponding superalloy and improve the ability to withstand the effects of neutron irradiation; the formation of helium bubbles, swelling and cracking that occur in regular nickel alloys.

Glazoff and INL are focusing on the thermodynamic modeling, diffusion, precipitation and DFT modeling of the nickel-ODS alloys. The modeling results will further guide experimental efforts and will reduce the number of critical experiments, saving both time and money.

INL's NUC benefits universities by leveraging research funding and providing access to INL researchers and the large array of nuclear-related facilities, including neutron reactors and examination equipment.

In return, INL gets a boost to its science and technology research by working with these universities. Another important aspect is creating a pipeline of research talent where students participating in NUC projects can perhaps get jobs at INL, Walck said.

"We've got some really exciting work going on," Walck said.

| Type of Award | Project Name | PI | PI Institution | Other Collaborators | | NEUP | Ni-based ODS alloys for Molten Salt Reactors | Djamel Kaoumi | North Carolina State University | Michael Glazoff (INL)

Peter Hosemann (UC, Berkeley)

Haiyan Zho (University of Idaho)

David Armstrong (Oxford University)

Michael Moody (Oxford University) | | NEUP | Demonstrating Reactor Autonomous Control Framework using Graphite Exponential Pile | Kaichao Sun | Massachusetts Institute of Technology | Benjamin Baker (INL)

Akshay Dave (MIT)

Kord Smith (MIT) | | NEET | Context-Aware Safety Information Display for Nuclear Field Workers | Pingbo Tang | Arizona State University | Ron Boring (INL)

Alper Yilmaz (Ohio State University)

Thomas Myers (Duke Energy) | | Joint R&D with NSUF Access | High Fluence Active Irradiation and Combined Effects Testing of Sapphire Optical Fiber Distributed Temperature Sensors | Joshua Daw | Idaho National Laboratory | Thomas Blue (Ohio State University)

Chrisitan Petrie (Oak Ridge National Lab)

Paul Ohodnicki (National Energy Technology Laboratory) | | VTR | Molten Salt Sweep Gas Control, Analysis, and Capture System to Support VTR Experiments | Tony Hill | Idaho National Laboratory | Massachusetts Institute of Technology

Hierarchical Data Format (HDF) Group | | ARPA-E | Next-Generation Metal Fuel | Michael Benson | Idaho National Laboratory

| Wade Marcum (Oregon State University)

John Hanson (Oklo)

|

By Erica Curless

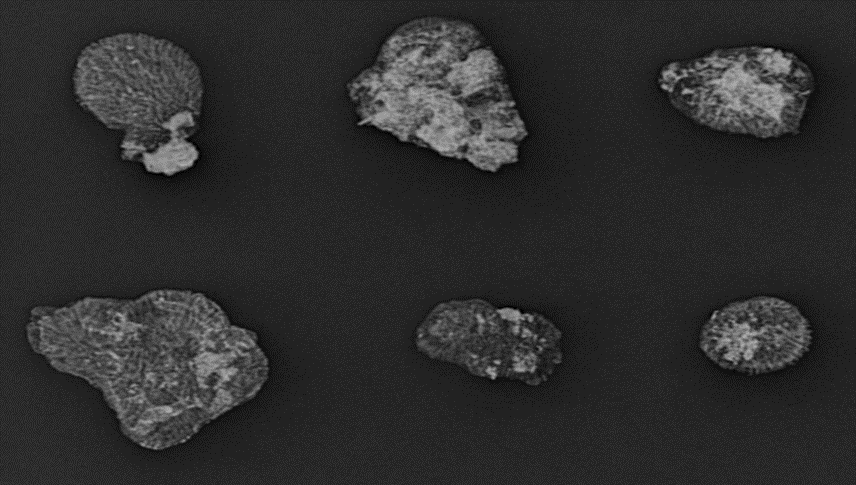

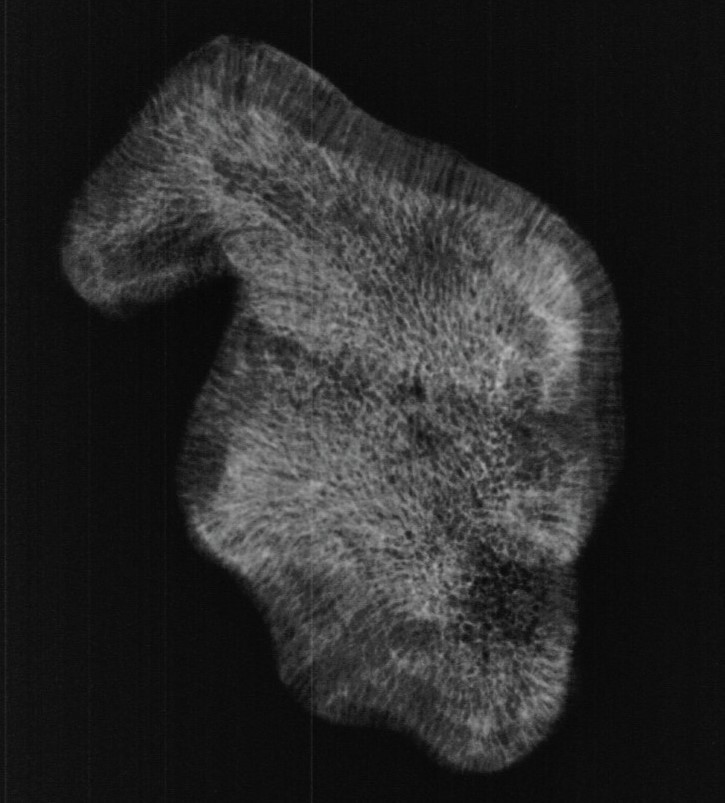

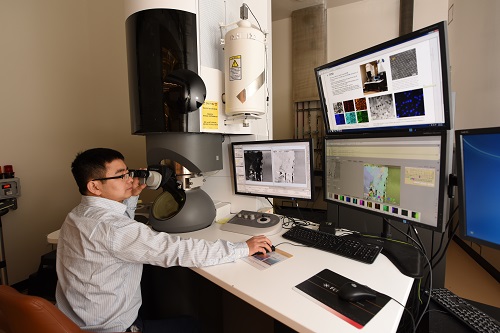

| 9/13/2019 | September 2019 | | | 2. Research |  | A tool for visualizing damage to materials made to withstand the harshest conditions inside a nuclear reactor is now being used to examine some of nature’s more delicate species. Tiny imperfections in nuclear fuel rods or changes to reactor components caused by the bombardment of radiation can have big impacts on performance and safety. Few methods exist to detect these problems without destroying the specimen itself. That’s why, for more than 40 years, nuclear energy researchers have used Idaho National Laboratory’s Neutron Radiography Reactor (NRAD), a 250-kilowatt research reactor, to peer inside nuclear fuel and other reactor components. Now, after a series of upgrades, INL scientists hope this powerful imaging technology can assist researchers in other scientific fields as well. Idaho State University biology student Amanda Smolinski is collaborating with engineers at NRAD to make images of Dragmacidon lunacharta, a sea sponge that is known to accumulate heavy metals in waters with high levels of pollution. Amanda Smolinski places sea sponges in front of the digital neutron imaging system at NRAD’s North Radiography Station. Smolinski hopes to use neutron radiographs to detect cadmium pollution in the sponges.The NRAD images will help Smolinski to learn more about how to find and clean up ocean pollution. In turn, Smolinski’s project will help NRAD establish itself as an imaging capability for a wide range of scientific pursuits, from learning about how battery chemistry changes during discharge to exploring the innards of dinosaur bones. Neutrons versus X-raysNeutrons are similar to X-rays in that they penetrate a specimen to create an image of internal structures. But neutrons are different. Instead of interacting with the electrons of an atom, like an X-ray, neutrons interact with the nucleus. Where X-rays show harder substances such as bone and teeth, neutron radiography shows the softer components of a specimen, especially substances containing hydrogen. Neutrons interact with these substances in a way that allows researchers to create images of internal soft structures using either traditional film or, now, digital imaging. Smolinski is using neutron imaging to examine the dried soft tissues of sea sponges for signs of cadmium, a naturally occurring metal that is used in metal manufacturing, the pulp and paper industry, and phosphate fertilizers. While some sea creatures need trace amounts of cadmium for their metabolism, high levels can be toxic for fish and other ocean wildlife. If researchers could learn more about how sponges absorb cadmium, it could help increase knowledge about how cadmium affects other sea life, where pollution is located, and how to mitigate its effects. The six sea sponges examined at NRAD.An X-ray image of six sea sponges containing cadmium.A neutron radiograph of the same six sea sponges taken at INL’s NRAD facility. The neutron radiographs show more internal details of the sponge’s structure, including possible cadmium contamination.Because D. lunacharta and similar species of sponge are so widespread, they could serve as a useful biomarker to gauge levels of pollution in the world’s oceans, said Smolinski. “They can be used to classify the type and, hopefully, quantify the amount of pollution in the marine environment from which they are harvested,” Smolinski said. “I’d like to use that information to create pollution maps.” The pollution maps could then be used to trace the pollution to its source and help with cleanup efforts. Creating a neutron radiograph To create the images, Smolinski offered her sponge specimens to NRAD, where her husband, Andrew Smolinski, works as a nuclear facility system engineer. Researchers at NRAD have developed digital neutron radiography and tomography capabilities using digital cameras that are shielded against radiation. Without digital radiography, taking a full set of film radiographs might take a month or more, and previous generations of computers might take several months to reconstruct a 3D image from hundreds of film images. Using the new digital cameras and state-of-the-art computers, researcher Dr. Aaron Craft, an R&D scientist at INL developing advanced neutron imaging systems, recently produced 421 radiographs in four hours, and reconstruction of a 3D image took under an hour. “This new system allows us to perform neutron tomography in less than a day, which makes it a practical research tool for scientific applications such as this,” Craft said. “It opens up new avenues of collaboration with universities, museums and other research institutions.”